The Importance of an Optical Measurement System in Industrial Applications

Optical measurement systems play a critical role in industrial applications. They offer high precision and assist in non-contact measurement, which is crucial for protecting delicate parts. These systems improve operational effectiveness and promote high quality control. Their execution is not without obstacles. Comprehending their significance and the complexities included can brighten their transformative capacity in modern manufacturing. What are the particular benefits and obstacles that these systems existing?

Comprehending Optical Measurement Solutions

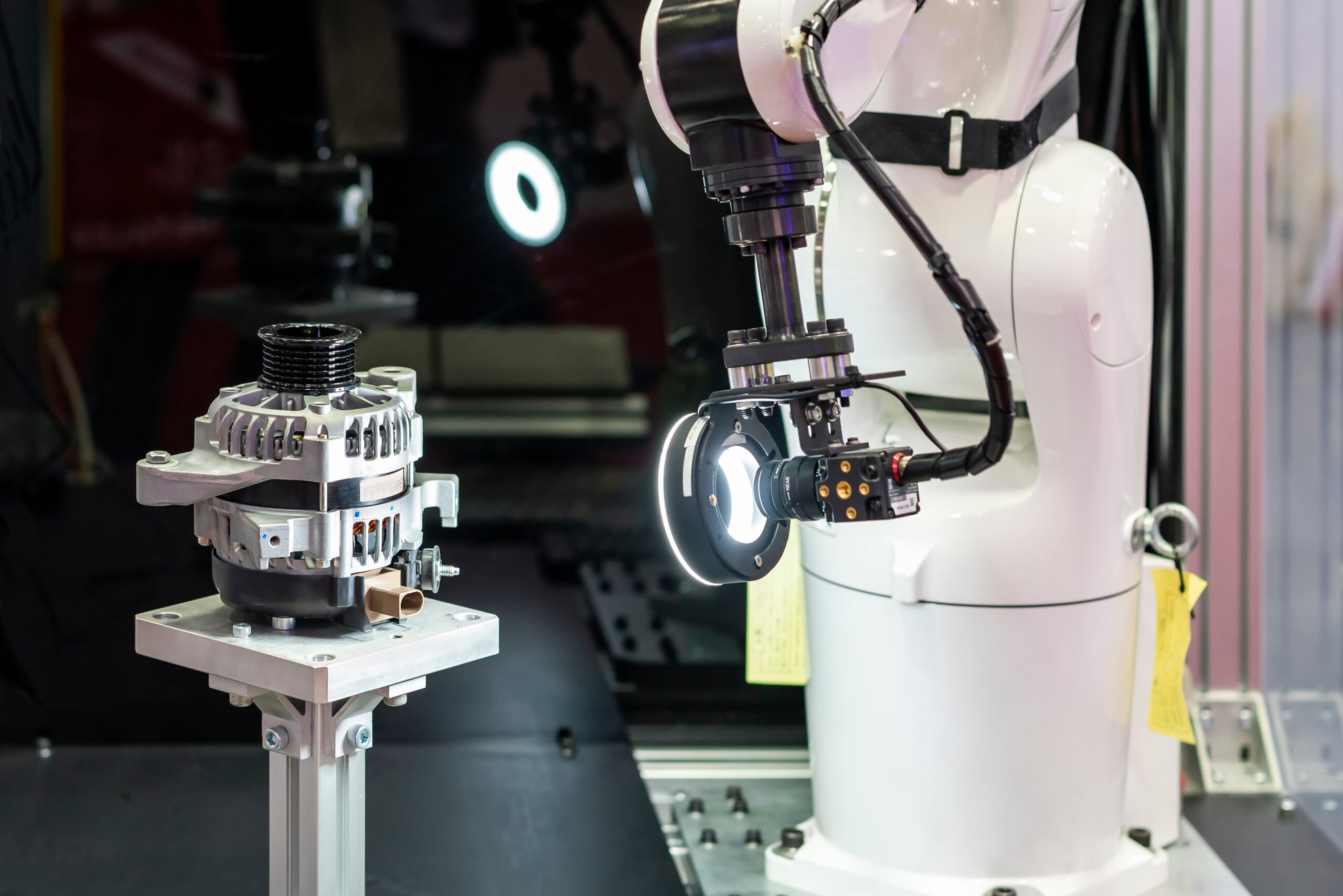

Optical measurement systems play an essential duty in various commercial applications by providing specific and accurate information collection. These systems use light to determine physical properties such as dimensions, surface profiles, and product qualities. The fundamental components typically consist of lasers, cams, and sensing units that catch and examine light mirrored from things. By using methods such as interferometry and photogrammetry, these systems can identify minute changes in form and dimension, which are critical for quality assurance and item consistency.Furthermore, optical measurement systems are non-contact, allowing them to analyze fragile or intricate items without triggering damages. They are flexible, discovering applications in areas like aerospace, automotive, and electronic devices manufacturing. The integration of innovative software program for data evaluation improves the performance of these systems, allowing real-time monitoring and comments. As industries advance, the relevance of optical measurement systems remains to expand, sustaining the demand for greater accuracy and effectiveness.

Key Benefits of Optical Measurement in Production

While typical measurement techniques usually include physical call and can present errors, the fostering of optical measurement systems in making offers significant advantages. These systems use non-contact techniques, decreasing the threat of damages to sensitive elements and making certain the stability of dimensions. Optical measurement gives high accuracy and accuracy, enabling producers to accomplish tight tolerances essential in affordable markets.Additionally, the speed of optical measurement systems boosts performance. fibre testing equipment. Rapid information purchase allows for real-time tracking, facilitating instant modifications in production procedures. This efficiency leads to minimized waste and enhanced resource allocation.Furthermore, the convenience of optical systems suits a large range of products and geometries, making them suitable for different applications. Their ability to incorporate flawlessly with automation modern technologies sustains Sector 4.0 campaigns, advertising smarter producing atmospheres. Overall, the vital benefits of optical measurement add substantially to boosting quality assurance and functional efficiency in modern-day production setups

Applications of Optical Measurement Equipments

Optical measurement systems play a vital function in numerous commercial applications, specifically in improving precision throughout making processes. They are integral to quality assurance and guarantee, ensuring that products satisfy rigid standards. Additionally, these systems sustain research study and growth campaigns by offering exact information for advancement and improvement.

Precision in Manufacturing Processes

In contemporary manufacturing, high precision is vital for making sure product quality and functional effectiveness. Optical measurement systems supply innovative capacities that significantly improve accuracy throughout the production procedure. These systems utilize light and imaging technologies to capture thorough measurements of elements, enabling makers to attain tight tolerances and exact dimensions. By integrating optical measurement into production workflows, companies can promptly identify variances from specs, consequently lowering waste and lessening rework. In addition, the non-contact nature of optical measurements permits examining fragile or delicate products without danger of damages. Inevitably, the adoption of optical measurement systems fosters a society of precision in production, leading to boosted efficiency and competition in the marketplace.

Top Quality Control and Assurance

Quality control in making greatly counts on exact measurement methods to assure that products meet recognized criteria. Optical measurement systems play a pivotal duty in this process, making it possible for precise analyses of measurements, surface top quality, and various other essential functions of made products. By utilizing high-resolution imaging and innovative evaluation formulas, these systems discover discrepancies from specifications, ensuring consistency throughout production. In addition, optical measurements can be non-destructive, maintaining the stability of items while facilitating quick analyses. The combination of these systems into top quality control procedures boosts performance and minimizes waste, inevitably adding to boosted product reliability. As sectors undertaking for excellence, the adoption of optical measurement modern technologies ends up being increasingly important for preserving competitive advantage and customer fulfillment.

Research and Growth Applications

As industries endeavor for advancement, optical measurement systems have arised as a crucial tool in r & d applications. fibre testing equipment. These sophisticated systems supply accurate measurements of products and parts, making it possible for engineers and researchers to get critical understandings into their residential properties and performance. Optical measurement innovations, such as laser scanning and interferometry, assist in the rapid prototyping of brand-new styles and the optimization of existing items. By capturing high-resolution information, researchers can identify problems and examine the impact of various criteria on product capability. In addition, these systems support interdisciplinary cooperation, bridging gaps in between different fields. The assimilation of optical measurement systems right into R&D processes eventually speeds up advancement timelines and fosters the development of advanced options in numerous industrial fields

Comparing Optical Measurement to Conventional Approaches

In contrasting optical measurement This Site systems to standard techniques, a number of vital factors emerge, consisting of precision and precision. Additionally, the speed of measurement and cost-effectiveness play substantial duties in determining the viability of each technique for industrial applications. This assessment highlights exactly how improvements in optical innovation may use benefits over conventional strategies.

Precision and Accuracy

Optical measurement systems supply considerable benefits in accuracy and precision contrasted to traditional measurement approaches. These systems utilize sophisticated innovation, such as lasers and high-resolution cams, to catch dimensional information with marginal error. On the other hand, traditional techniques frequently depend on mechanical devices that can present variability because of human mistake or material wear. Optical systems can accomplish micrometer-level precision, ensuring constant outcomes also in complicated geometries. In addition, they offer non-contact measurement, decreasing the risk of damaging delicate elements. This capacity is specifically helpful in sectors where resistances are critical, such as aerospace and automobile manufacturing. Consequently, the adoption of optical measurement modern technology enhances quality assurance and lowers the likelihood of flaws, inevitably enhancing general production performance.

Rate of Measurement

The benefits of optical measurement systems extend beyond accuracy and precision to consist of substantial enhancements in measurement speed. Standard measurement techniques frequently require lengthy arrangements and hands-on computations, which can decrease manufacturing procedures. On the other hand, optical systems utilize innovative modern technologies such as laser scanning and imaging, enabling quick information purchase and handling. This effectiveness enables real-time dimensions, facilitating quicker decision-making in producing environments. The ability to record large quantities of information in a short time boosts throughput and performance, giving organizations an one-upmanship. In addition, with reduced measurement times, optical systems minimize downtime connected with inspections, better enhancing procedures. The rate of measurement in optical systems substantially adds to total functional effectiveness in commercial applications.

Cost-Effectiveness Analysis

A thorough cost-effectiveness analysis exposes that optical measurement systems frequently give significant financial benefits over traditional techniques. These systems generally lower the requirement for comprehensive physical arrangements, reducing labor costs and downtime during measurement processes. Optical approaches can also yield faster outcomes, resulting in raised productivity and decreased operational costs. Furthermore, the accuracy offered by optical dimensions lowers the likelihood of expensive errors, which can emerge from hand-operated treatments and traditional strategies. In the future, the first financial investment in optical innovation is often countered by savings in sources, time, and improved item high quality. Sectors that embrace optical measurement systems might locate themselves not only improving efficiency yet likewise accomplishing a much more desirable cost-benefit ratio contrasted to traditional approaches.

The Function of Automation in Optical Measurement

While lots of sectors significantly depend on precision and effectiveness, automation has actually become an essential element in enhancing optical measurement processes. By integrating automated systems, organizations can significantly improve measurement precision and decrease human mistake. Automated optical measurement systems use innovative formulas and sensing units to supply real-time data analysis, assisting in quicker decision-making and process adjustments.Additionally, automation permits for regular dimensions across various production runs, guaranteeing that top quality requirements This Site are kept. The scalability of automated optical measurement systems makes them suitable for diverse applications, from quality assurance in making to evaluation in semiconductor production.Furthermore, these systems can be effortlessly integrated right into existing production configurations, advertising a smooth shift towards much more reliable operations. In general, the role of automation in optical measurement is pivotal, offering improved dependability, decreased labor expenses, and improved functional effectiveness, eventually driving commercial competition.

Obstacles and Factors To Consider in Implementation

Carrying out optical measurement systems, despite the benefits of automation, offers numerous challenges and considerations that companies should navigate. One significant challenge is the combination of these systems right into existing workflows, which might need substantial modifications in procedures and staff member training. Organizations has to additionally attend to the compatibility of optical measurement innovations with existing equipment and software.Additionally, the irregularity of products and ecological conditions can affect measurement precision, requiring robust calibration and upkeep protocols. Price is another important consideration, as initial investments can be significant, and organizations have to consider these expenses against possible effectiveness gains. Data management additionally presents obstacles, as the volume of details created needs effective systems for storage, evaluation, and interpretation. Making sure conformity with market criteria and guidelines includes an additional layer of complexity to the implementation procedure, needing cautious planning and implementation.

Future Fads in Optical Measurement Technology

As markets remain to progress, innovations in optical measurement technology are set to transform their functional landscapes. Arising fads suggest a shift in the direction of increased automation and assimilation with expert system, boosting the precision and effectiveness of dimensions. Flexible optics is gaining traction, permitting systems to adjust in real-time to varying ecological problems, thereby lessening mistakes. Furthermore, the miniaturization of optical sensors is enabling their deployment in extra small and diverse settings, expanding application opportunities in markets such as aerospace and manufacturing.Additionally, the advancement of 3D optical measurement strategies is changing high quality control processes, providing more substantial information evaluation. Innovations in information processing algorithms are additionally expected to linked here streamline the analysis of complicated measurements, making understandings a lot more easily accessible. Collectively, these trends reflect a future where optical measurement innovation not only enhances accuracy but likewise boosts operational dexterity, positioning markets to better satisfy progressing needs.

Regularly Asked Questions

How Do Optical Measurement Solutions Ensure Data Precision?

Optical measurement systems assure information accuracy with exact calibration, advanced formulas, and high-resolution imaging. These parts collaborate to reduce mistakes, enhance measurement consistency, and give reliable results important for different industrial applications and processes.

What Is the Typical Life Expectancy of an Optical Measurement System?

The typical life expectancy of an optical measurement system varies, commonly varying from five to fifteen years. Factors affecting long life include use strength, environmental problems, upkeep methods, and technical developments that might necessitate upgrades or replacements.

Can Optical Measurement Systems Be Custom-made for Certain Industries?

What Training Is Required for Running Optical Measurement Systems?

Training for operating optical measurement systems usually includes understanding system parts, software application use, calibration methods, data evaluation, and safety and security protocols. Individuals usually engage in hands-on technique and may complete qualification courses to enhance their efficiency.

Just How Do Ecological Variables Influence Optical Measurement Results?

Environmental factors, such as temperature, moisture, and lights conditions, significantly affect optical measurement outcomes. Variations in these components can bring about errors, affecting the precision and integrity of measurements taken by optical systems in different settings.